As we’ve discussed in past Sparc Notes, the use of battery energy storage systems has exploded in the past few years, especially in the NY Metro area. The following is a list of important things to consider when designing battery energy storage water spray systems in NYC. The focus in this case is to follow the design intent and requirements for a water spray system.

What is a Water Spray System?

A water spray system utilizes open spray nozzles to provide protection against the spread of lithium-ion battery fires. Specifically for New York City, the system shall provide complete surface coverage by the nozzle spray. The goal is to protect against the heating of an adjacent ESS and to limit propagation, not extinguish the fire. This means that a water spray system will not prevent a thermal runaway reaction within the container, but will aim to prevent the fire from extending beyond the ESS container boundary. This is different from a building sprinkler system which aims to control or extinguish the fire.

Applicable codes

The design for a water spray system must adhere to the following codes and standards:

- NPFA 13, Standards for Installation of Sprinkler Systems

- NFPA 15, Standard for Water Spray Fixed Systems for Fire Protection

- RCNY 608-01, Outdoor Stationary Storage Battery Systems

These standards are to supplement the applicable Building (BC) and Fire Codes (FC) for a given location. Specifically for New York City, the design must also comply with the following:

- Any modifications to the above by Appendix G of the NYC Fire Code and/or Appendix Q of the NYC Building Code.

- New York City Fire Department (FDNY) Rule 3 RCNY 608-01, “Outdoor Stationary Storage Battery Systems”

- New York City Fire Department Certificate of Approval for the specific ESS container to be installed.

- UL 9540A Testing Report, portions of which may apply to Water Spray Systems

Type of ESS installation

While the codes and standards listed above shall apply, it is also important to consult with the manufacturers’ specifications and requirements for the ESS to be installed. This can include restrictions on clearances, which will have an impact on the locations and orientations of the open spray nozzles and associated piping. It can also impact the structural and bracing requirements for the water spray system supports, which are extremely critical items especially as it relates to providing manufacturer required access to the ESS while ensuring proper support to the piping.

Flood zone

The location of the lot where the new BESS is to be installed will dictate whether additional requirements apply, specifically regarding flood protection. For New York City, the FDNY requires the use of DEP Flood Zone maps to determine if the site is located within a designated flood zone.

Nozzle coverage – Hydraulics

The goal for the battery energy storage water spray systems in NYC is to provide complete wetting of the surface of the ESS container. To do this the system utilizes open water spray nozzles. Depending on the manufacturer, the characteristics of the open nozzle can vary, including differences in minimum operating pressure, maximum working pressure, and discharge flow.

When trying to determine the hydraulic characteristics and requirements, the hydraulic calculations must be adjusted to account for the area of coverage for each open nozzle. This will determine the flow and pressure requirements for the system, and whether the supply will be sufficient.

Nozzle Placement and Orientation

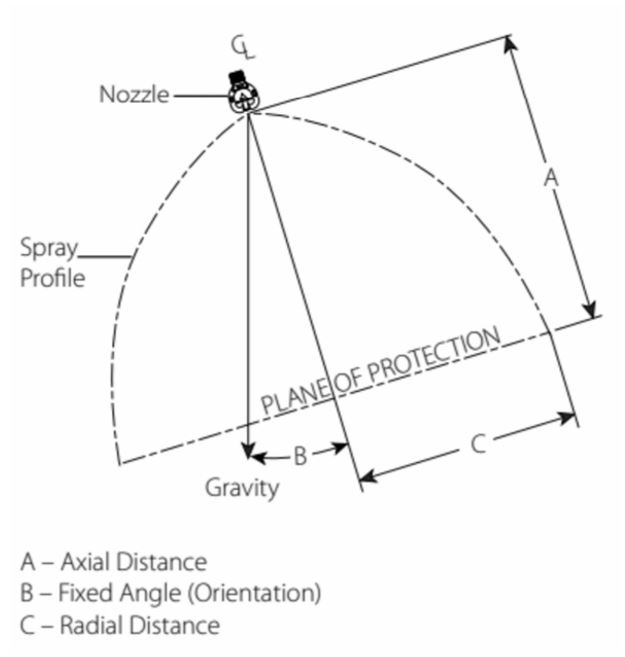

From the nozzle point of view, the Axial distance is the maximum throw the nozzle can provide directly forward. Conversely, the Radial distance is the maximum throw the nozzle provides to either side.

Finally, the Fixed angle determines the orientation the nozzle is installed at, with pendent orientation being 0° Fixed Angle and upright being 180° Fixed Angle.

The final variable to account for in this calculation is the Spray Angle, which determines the Spray Profile for each nozzle. Effectively, a smaller Spray Angle results in a narrower Spray Profile, and vice versa.

Typically, open spray nozzles are not differentiated by orientation, but by K-factor and Spray Angle. All these attributes must be considered when selecting the appropriate nozzle(s). Each listed attribute also affects the surface area coverage of each nozzle’s spray area. In our designs, we ensure all aspects are accounted for to provide the most complete water spray protection possible.

Typically, open spray nozzles are not differentiated by orientation, but by K-factor and Spray Angle. All these attributes must be considered when selecting the appropriate nozzle(s). Each listed attribute also affects the surface area coverage of each nozzle’s spray area. In our designs, we ensure all aspects are accounted for to provide the most complete water spray protection possible.

NYC FDC and Supply Requirements

The FDNY requires the use of approved 2-way Siamese outlet Fire Department connections. Thus, it is important to match the number of outlets provided for a given design with the required flow the system will demand. Approved signage and vehicle protection shall be provided as needed at each FDC installation. It is also important to consider the engine which will act as the primary water supply to the system. Just like a standard fire pump, each engine has a flow and pressure rating.

Conclusion

There are multiple considerations to be made when designing battery energy storage water spray systems in NYC. Each of these design considerations and resulting equipment layouts can have an effect on the cost of the system, as well as the overall maintenance through the life of the system. Optimization of these systems during the design stage is especially critical. Sparc Fire Protection has many years of experience interfacing with the local Authorities Having Jurisdiction (AHJs) including the FDNY and DOB, especially regarding water spray systems. This has allowed us to have a unique insight into the requirements for the protection of ESS installations. Our experience also allows us to be fully aware of upcoming and pending changes that are being discussed, meaning our water spray designs are always up to date and approval ready. Contact us today to discuss how we can help with your design!

Leave a Comment